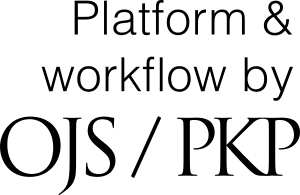

Caracterización de uniones soldadas robotizadas GTAW-P sin metal de aporte en acero inoxidable ferrítico AISI 430

DOI:

https://doi.org/10.29105/qh10.2-122Palabras clave:

Acero inoxidableferrítico 430, soldadura robotizada GTAW-P, micrografias panorámicas, tamaño de granoResumen

Se estudió el efecto de la corriente pulsada y velocidad de avance de soldadura sobre la resistencia mecánica bajo carga de tensión, zonas microestructurales, tamaño de grano y número de tamaño de grano ASTM G en la Zona Afectada por el Calor (ZAC) de uniones soldadas robotizadas GTAW-P por fusión en lámina de acero inoxidable ferrítico AISI 430 con 1.5 mm de espesor. Para la caracterización mecánica se usaron pruebas de tracción para evaluar la resistencia a la tensión. Se aplicó microscopía óptica para la evolución microestructural y procesamiento digital de imágenes (PDI) para la obtención de micrografias panorámicas de amplio formato de uniones transversales. Los resultados sugirieron que la condición óptima (JR1) fue la combinación de la corriente de soldadura (61/83.9 A), arco pulsado (15 Hz) y velocidad de soldadura (381 nnn/min), lo que resultó en la fusión completa del metal con geometría adecuada del cordón, resistencia máxima a la tracción de 457 MPa, tamaño de grano mediano (10.84 µm), ferrita aliotromórfica dentro de la ZAC recristalizada y ferrita tipo placa Widmanstatten secundaria dentro del metal fundido.

Descargas

Citas

-[1] AWS, Welding Handbook 9.4, EUA: AWS, 2011.

-[2] E. Bayraktar, J. Moiron, D. Kaplan, "Effect of welding conditions on the formability characteristics of thin sheet steels: Mechanical and metallurgical effects," Journal of Materials Processing Technology, vol. 175, pp. 20-26, 2006. doi: 10.1016/j. jmatprotec.2005 .04.007 DOI: https://doi.org/10.1016/j.jmatprotec.2005.04.007

-[3] M.O.H Amuda, E. T. Akinlabi, S. Mridha, "Influences of Energy Input and Metal Powder Addition on Carbide Precipitation in AISI 430 Ferritic Stainless Steel Welds," Materials Today, vol. Proceedings 4, pp. 234-243, 2017. DOI: https://doi.org/10.1016/j.matpr.2017.01.017

-[4] YOU Xiang-mi, JIANG Zhou-hua, LI Hua-bing "Ultra-Pure Ferritic Stainless Steels----Grade Refining Operation and Application," Journal of Iron and Steel Research lnternational, vol. 14, nº 4, pp. 24-20, 2007. doi.org/10.1016/S1006-706X(07)60053-3 DOI: https://doi.org/10.1016/S1006-706X(07)60053-3

-[5] P. Giridharan, N. Murugan, "Optimization of pulsed GTA welding process parameters for the welding of AISI 304L stainless steel sheets," Advanced Manuf Technol, vol. 40, pp. 478-489, 2009. DOI: https://doi.org/10.1007/s00170-008-1373-0

-[6] M.O.H. Amuda, S. Mridha, "Comparative evaluation of grain refinement in AISI 430 FSS welds by elemental metal powder addition and cryogenic cooling," Materials and Design, vol. 35, pp. 609---618, 2012. doi:10.1016/j.matdes.2011.09.066 DOI: https://doi.org/10.1016/j.matdes.2011.09.066

-[7] M.O.H. Amuda, S. Mridha, "Grain refinement and hardness distribution in cryogenically cooled ferritic stainless steel welds," Materials and Design, vol. 4 7, pp. 365-371, 2013. dx.doi.org/10.1016/j. rnatdes.2012.12.008 DOI: https://doi.org/10.1016/j.matdes.2012.12.008

-[8] ASTM, A240/A240M - 14 Standard Specification for Chromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip for Pressure Vessels and for General Applications, West Conshohocken, PA: ASTM Intenational, 2014.

-[9] ASTM E353, Standard Test Methods for Chemical Analysis of Stainless, Heat-Resisting, Maraging, and Other Similar Chrornium-Nickel-Iron Alloys, West Conshohocken, PA: DOI: 10.1520/E0353-14, 2014. DOI: https://doi.org/10.1520/E0353-14

-[10] P. Guiraldenq, O. Hardouin-Duparc, "The genesis of the Schaeffier diagram in the history of stainless," Metallurgical Research & Technology, pp. 114, 613, 2017. DOI: https://doi.org/10.1051/metal/2017059

-[11] M. Gurrama, A. Kumar, P. Ravinder, G. Madhusudhan, "Effect of copper and aluminium addition on mechanical properties and corrosion behaviour of AISI 430 ferritic stainless steel gas tungsten are welds,"journal of materials reseach and technology, vol. 2, nº3, pp. 238-249, 2013. DOI: https://doi.org/10.1016/j.jmrt.2013.02.009

-[12] Akhilesh Kurnar Singh, Vidyut Dey, Ram Naresh Raí "Techniques to improveweld penetration in TIG welding (A review)," Materials Today: Proceedings, Vols.4 Issue 2, Part A, pp. Pages 1252-1259, 2017. DOI: https://doi.org/10.1016/j.matpr.2017.01.145

-[13] AWS, D 1.6 Structural Welding Code- Stainless Steel, Miami, FL: American Welding Society, 2007.

-[14] M. Gurrama , A. Kumar P. Ravinder Reddy , G. Madhusudhan Reddy, , "Influence of grain refining elements on mechanical properties of AISI 430 ferritic stainless steel weldments - Taguchi approach,," Materials & Design, vol. 36, pp. 443450, 2012. DOI: https://doi.org/10.1016/j.matdes.2011.11.063

-[15] AWS, Welding Inspection Technology, Miami, Florida: AW S, 2005.

-[16] I. Guzmán-Flores, B. Vargas-Arista, J. Gasca-Dominguez, C. Cruz-Gonzalez, M. González-Albarrán, J. del Prado-Villasana, "Effect of Torch Weaving on the Microstmctnre, Tensile and Impact Resistances, and Fracture of the HAZ and Weld Bead by Robotic GMAW Process on ASTM A36 Steel," Soldagem & lnspecao, vol. 22, nº 1, pp. 72-86, 2017. doi.org/10.1590/0104-9224/SI2201.08 DOI: https://doi.org/10.1590/0104-9224/si2201.08

-[17] ASTM, E-8 -E8M Standard Test Methods for Tension Testing of Metallic Materials, West Conshohocken: United States.

-[18] ASTM, A370 Standard Test Methods and Definitions for Mechanical Testing of Steel Products, West Conshohocken: ASTM Intenational.

-[19] ASTM, E-3 Standard Guide for Preparation of Metallographic Specimens, West Conshohocken, EU: ASTM Intenational, 2011.

-[20] ASTM, El 12-96 Standard test methods for determining average grain size, Philadelphia: ASTM, 2004.

-[21] G. Thewlis, "Classification and quantification of microstructures in steels," Materials Science and Technology, vol. 161, nº20 DOI 10.1179/026708304225010325,p p. 143, 2004. DOI: https://doi.org/10.1179/026708304225010325

-[22] Tomasz, Wegrzyn, Piwnik, J. Stali, Spawanie, Chlodzeniem, Mikrojetowym., "Low Alloy Steel Welding with Micro-Jet Cooling.," Archives of Metallurgy and Materials., vol. 57, nº2, pp. doi 10.2478/vl0172-012-0056-x., 2012. DOI: https://doi.org/10.2478/v10172-012-0056-x

-[23] K. Devendranath Ramkumara, Aditya Chandrasekhara, Aditya Kumar Singha, "Comparative studies on the weldability, microstructure and tensile properties of autogeneous TIG welded AISI 430 ferritic stainless steel with and without flux," Journal of Manufacturing Processes, vol. 20, pp. 54-69, 2016. DOI: https://doi.org/10.1016/j.jmapro.2015.09.008

-[24] J. Lippold, D. Kotecki, Welding metallurgy and weldability of stainless steel, USA: John Wiley and Sons, 2005.

Descargas

Publicado

Cómo citar

Número

Sección

Licencia

Derechos de autor 2020 Graciela Rosel, Benjamín Vargas, Verónica Estrella, Eva Cervantes, Jaime Taha, Celso Cruz

Esta obra está bajo una licencia internacional Creative Commons Atribución 4.0.