Comparison of mesh grinding and chemical washing techniques for the beneficiation of kaolins used in the white cement industry.

DOI:

https://doi.org/10.29105/qh5.1-203Keywords:

ceramics, minerals, multilayer structureAbstract

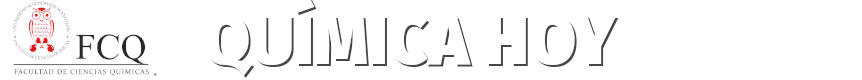

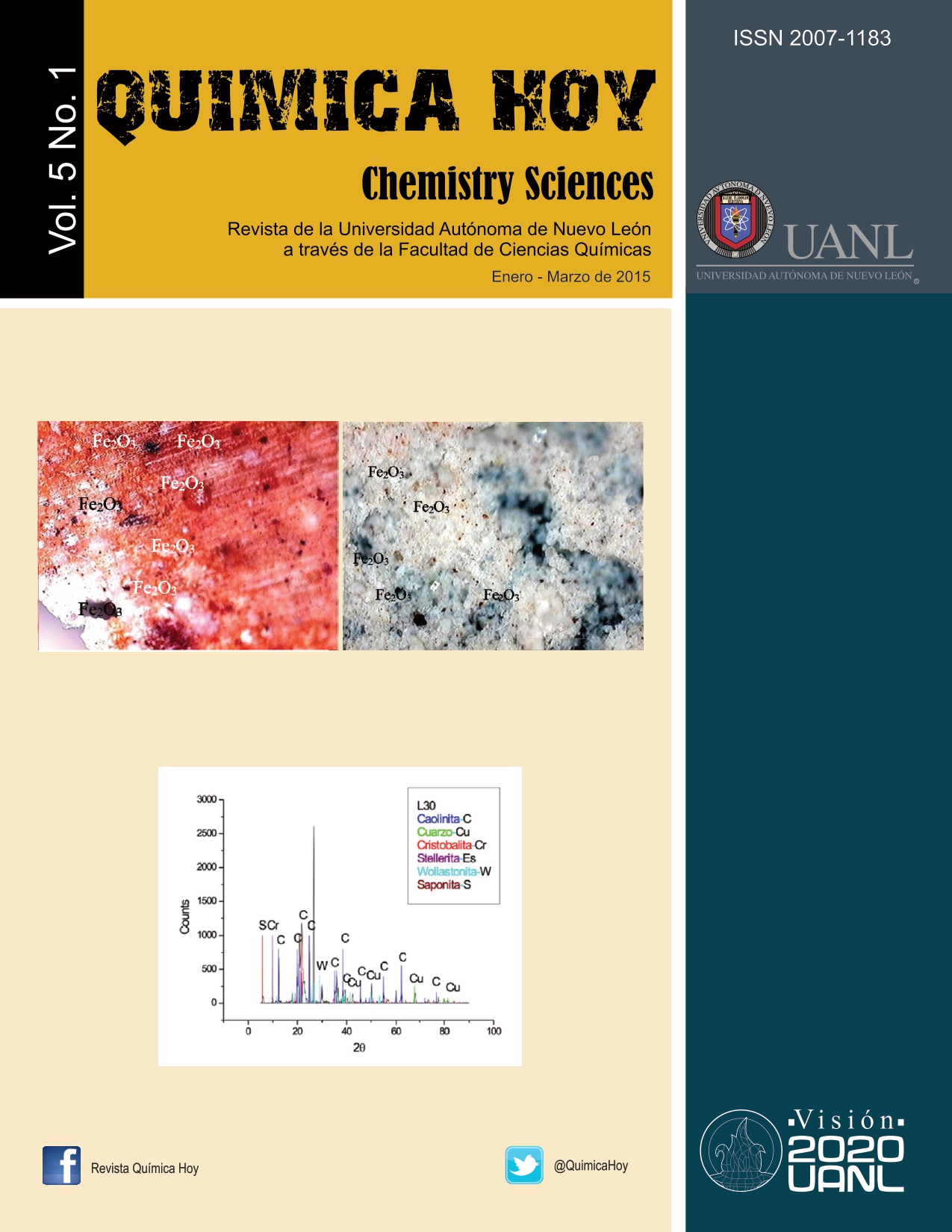

Kaolins are hydro aluminum silicates which are either monoclinic or triclinic in structure in accordance to their origin. Some common applications of kaolins are paper products, paints, catalyzers, white cement, etc. In the present research four different kaolins which were extracted from Villa de Reyes, S.L.P.; Mexico, were beneficiated using two different techniques: mesh grinding and chemical washing, in order to meet the requirements for the white cement industry, i.e. the mass content of Fe2O3 should be less than two percent of the total kaolin mass. XRD, Optical Microscopy, Colorimetry analysis were performed on the four studied kaolins. Mesh grinding and chemical washing techniques showed a similar degree ofbeneficiation. XRD analysis showed six different phases that make up the four different kaolins and are: saponite, kaolinite, wollastonite, stellerite, crystoballite and quartz. Most of Fe2O3 was located in the kaolinite, wollastonite and crystoballite phases, as could be corroborated by the combination of XRD, Optical Microscopy and Colorimetry analysis.

Downloads

References

-[1] Borchardt-Ott, W. Crystallography, 2nd ed; Springer: 1995 DOI: https://doi.org/10.1007/978-3-642-57754-3

-[2] Taylor, H. F. W.; Brunauer, Stephen, La química de los cementos, 1st ed.; Bilbao: Urmo, 1967

-[3] Zehany Wang, Study on the Processfor Puryfying Naturally Ocurring Sílice to High Purity Quartz Powder._September, 1997

-[4] Campos A. R.; Chaves A. P. Technological Aspects on the Beneficiation of Candiota Coal._September, 1997

-[5] P.N. Deo, K.S. Raju,Processing of lndian Kaolin Clays,_September,1997

-[6] Organismo Nacional de Normalización y Certificación de la Construcción y Edificación, S.C. Norma Mexicana NMX-C-ONNCCE-1999. Industria de la Construcción Cementos Hidráulicos - Especificaciones y Métodos de Prueba.

-[7] Pickering, Jr. et al., Processfor Whitening Kaolin, U.S. Patent: 5,545,599. August, 1996

-[8] Shi, et al., Process for Removing Impurities fromKaolin Clays, U.S. Patent: 5,522,986. June, 1996

-[9] EI-Shall; Dewatering Method and Agent,_U.S. Patent: 5,449,464. September, 1995

-[10] Norris, et al., Kaolin Clays which are Conditioned prior to Removing Impurities U.S. Patent: 6,007,618. December, 1999

-[11] Behl, et al., Method for Separating Mixture of Finely Divided Minerals U.S. Patent: 5,535,890. July, 1996

-[12] Behl, et al., Colored Titanoferous Coating Pigment Obtained as a Flocculated By- Product in a Kaolin Purification Process U.S. Patent: 5,688,315. November, 1997

-[13] Williams, et al., Method far Separating Mixture of Finely Divided Minerals U.S. Patent: 5,603,411. February, 1997

-[14] Behl, et al., Colored Titanoferous Coating Pigment Obtained as a Flocculated By-Product in a Kaolin Purification Process U.S. Patent: 5,584,394. December, 1996

-[15] Norris, et al., Process far Conditioning Kaolin Clays Prior to Removing Impurities U.S. Patent: 5,685,899.November, 1997

-[16] Shi, et al.,Process for Removing Impurities from Kaolin Clays U.S. Patent: 5,891,326. April, 1999

-[17] Green et al., Use of Ultraflotation in Kaolinitic Clays U.S. Patent: 2,990,958. May, 1998

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2015 Ma. Idalia Gómez de la Fuente, Juan Pablo Salinas Estevane

This work is licensed under a Creative Commons Attribution 4.0 International License.